The TAC Module, or Throttle Actuator Control Module, is an essential part of a vehicle’s fuel delivery system. It regulates the air and fuel entering the engine and helps maintain optimal performance. However, it can malfunction for various reasons and cause symptoms like decreased fuel efficiency, poor engine performance, and low power output. This article explains the common symptoms of a bad TAC Module and a troubleshooting guide to help diagnose the fault.

What Is a TAC Module?

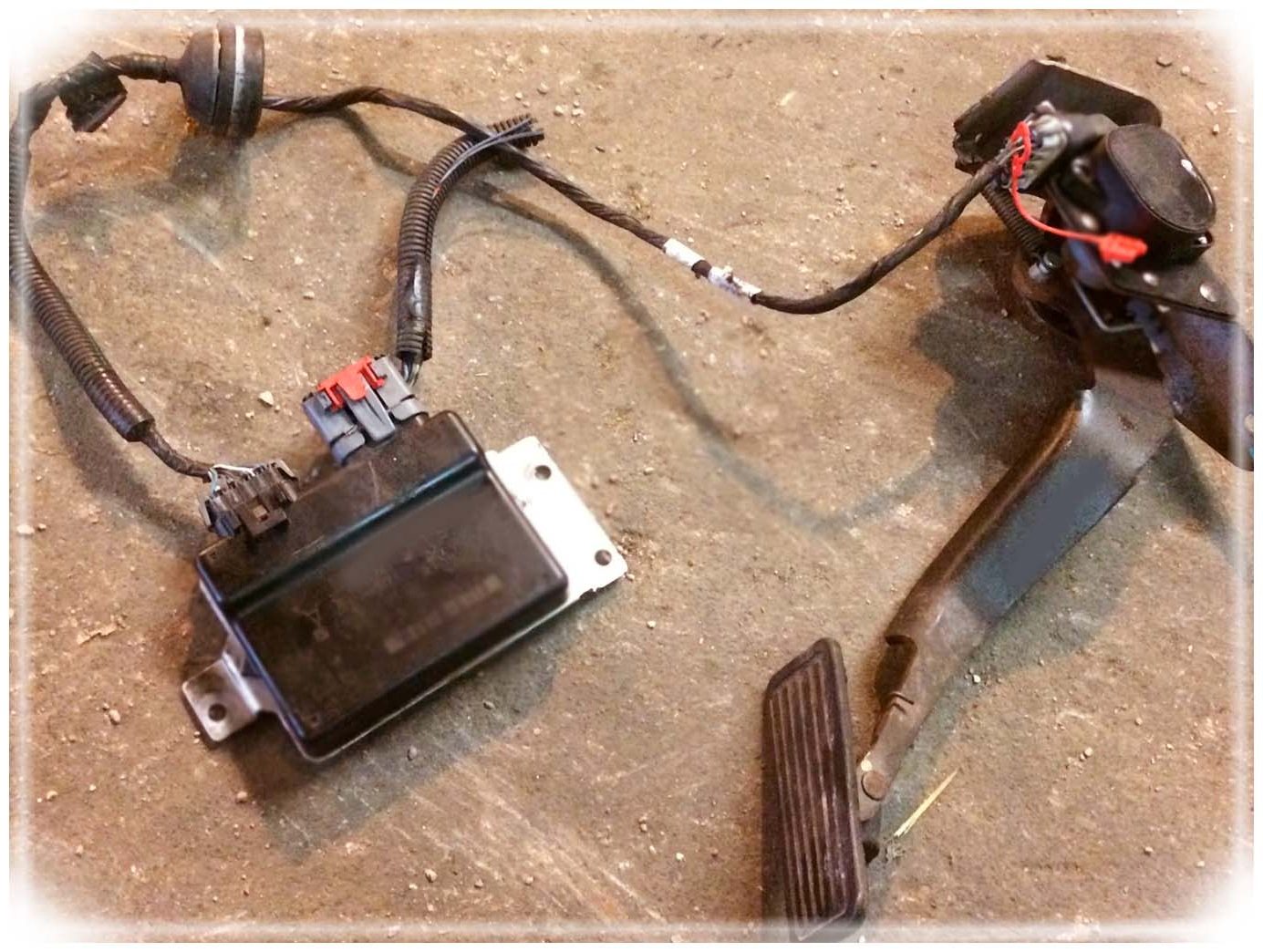

A TAC (Throttle Actuator Control) Module is an electronic device in a vehicle that controls the throttle position, acceleration, and deceleration functions. It is responsible for regulating the air entering the engine so it can run properly. The TAC Module monitors the accelerator pedal position and engine speed to calculate how much air to let in or keep out of the motor. It then adjusts the throttle plate accordingly. This helps maintain optimal performance and fuel economy while avoiding problems like stalling or rough idling. The TAC Module also works with other sensors and systems in your vehicle to provide better control over acceleration, braking, and fuel efficiency. Ultimately, this helps your car run smoother and more efficiently while ensuring you get maximum power out of your engine when needed.

Symptoms of a Bad TAC Module

The most common symptoms of a bad TAC Module are decreased fuel efficiency, poor engine performance, and low power output. Other common signs include difficulty starting the engine, stalling at idle, jerking while accelerating, and the SES (Service Engine Soon) or CEL (Check Engine Light) coming on.

Decreased Fuel Efficiency: One of the most common symptoms of a bad TAC Module is decreased fuel efficiency. If your vehicle’s fuel efficiency has dropped significantly, it could be due to an issue with its TAC Module.

Poor Engine Performance: Another symptom of a faulty TAC Module is poor engine performance. Your vehicle may struggle to accelerate or have difficulty climbing hills due to inadequate power output due to malfunctioning parts in its fuel delivery system, such as the TAC module or other components connected to it, like flow sensors or injectors.

Low Power Output: If your vehicle is not producing enough power output, it could be a sign that the TAC Module is malfunctioning. Low power output could also be due to a faulty ignition system, fuel injectors, or other components related to engine performance.

Diagnosing a Faulty TAC Module

- Thorough Visual Inspection: Start by visually inspecting the TAC Module, its connections, and surrounding components for signs of wear or damage. Check for loose or corroded wiring, cracked or loose connectors, and any other signs of damage that could indicate a faulty module.

- Check TAC Module Connections: Next, check all the wires connected to the TAC Module to ensure they are connected correctly and securely. Ensure all connections are clean and free of corrosion.

- Scan for Trouble Codes: Using an OBD-II scanner, check for trouble codes related to the TAC Module, such as P0221 (Throttle/Pedal Position Sensor/Switch B Circuit Range/Performance) or P0222 (Throttle/Pedal Position Sensor/Switch B Circuit Low Input). If any codes are detected, try resetting them first before replacing any parts.

- Test Throttle Plate Functionality: With the engine running at idle speed, inspect how smoothly the throttle plate moves when actuated by pressing down on the accelerator pedal. Check that there is no sticking or binding in its movement, which could indicate a faulty TAC module.

- Replacement: Once you have confirmed an issue with your vehicle’s TAC Module, it’s time to replace it. Ensure you use a genuine replacement part from a reputable supplier and follow the manufacturer’s instructions for installation.

By following these steps, you can better understand whether a faulty TAC module is causing issues with your vehicle’s throttle control system. Remember, if you are unsure or unable to diagnose the problem yourself, it is recommended to seek the assistance of a qualified automotive technician.

Conclusion

A Throttle Actuator Control (TAC) Module is essential to modern cars and trucks. It regulates the amount of air and fuel entering the engine for optimal performance, but it can malfunction due to various issues. Common symptoms of a bad TAC Module include decreased fuel efficiency, poor engine performance, and low power output. Diagnosing a faulty TAC Module involves an in-depth analysis of its associated components like wiring harnesses and connectors and the Throttle Position Sensor (TPS). If you cannot diagnose the problem, you should seek help from a professional automotive technician.

Add Comment