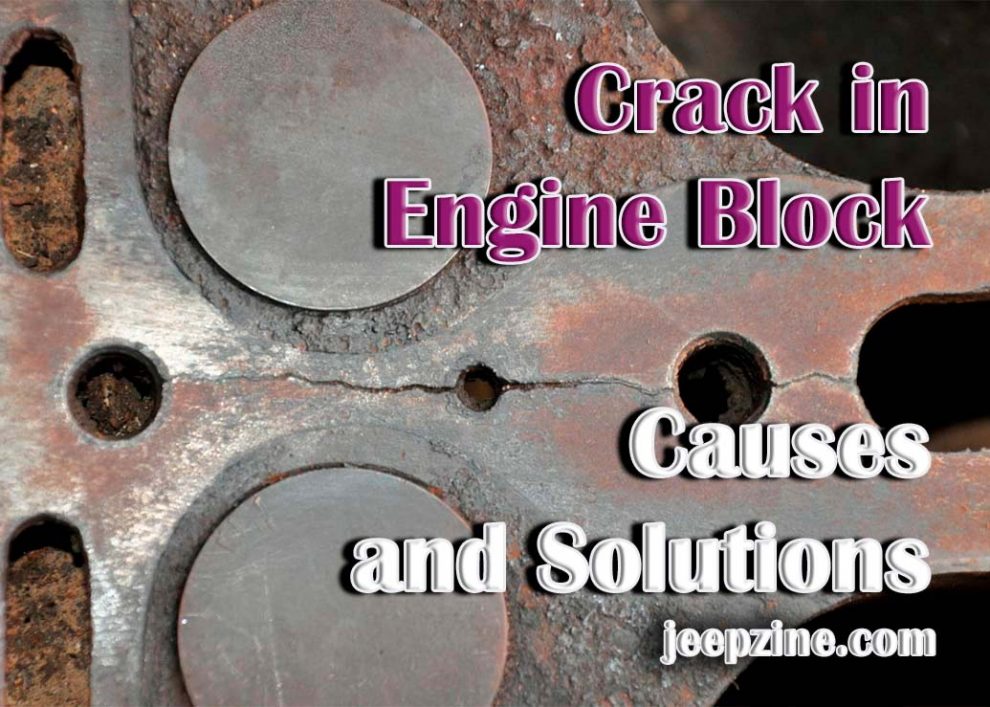

A crack in an engine block is a significant issue and can cause serious damage to your vehicle. Identifying and addressing any signs of wear or damage as soon as possible is important to prevent further damage or costly repairs. In this article, we’ll discuss the causes of engine block cracks, how to check for them, and what you can do if you find one.

Causes of Crack in Engine Block

Cracks in engine blocks can occur for various reasons, and they are a significant concern as they can lead to engine failure and costly repairs. Some common causes of cracks in engine blocks include:

-

Overheating: One of the most common reasons for engine block cracks is overheating. When the engine operates at excessively high temperatures, the metal can expand beyond its limits, causing stress and eventually leading to cracks in the block.

-

Coolant Leaks: A low coolant level or leaks in the cooling system can result in insufficient cooling, leading to overheating and subsequent cracks in the engine block.

-

Freezing: If the engine is exposed to extremely cold temperatures without adequate antifreeze protection, the coolant can freeze and expand, exerting pressure on the engine block and potentially causing cracks.

-

Poor Maintenance: Inadequate maintenance, such as neglecting regular oil changes, can lead to increased wear and tear on engine components, making them more susceptible to cracks.

-

Engine Vibration: Excessive engine vibration, which misaligned or damaged engine mounts could cause, can lead to stress and fatigue in the engine block, eventually causing cracks.

-

Manufacturing Defects: Although rare, manufacturing defects in the engine block’s casting process or material composition can weaken its structural integrity, making it more prone to cracking.

-

Engine Detonation or Knocking: Detonation (pre-ignition) or knocking inside the cylinders can generate high-pressure shock waves that stress the engine block, potentially leading to cracks.

-

Improper Installation: If the engine is not installed correctly or certain components are not torqued to the appropriate specifications during assembly, it can cause uneven stress distribution in the block, leading to cracks over time.

-

High Mileage or Wear and Tear: As an engine ages and accumulates a high mileage, its components can weaken due to wear and tear, increasing the risk of cracks.

-

External Impact: Accidents or collisions can cause external forces on the engine block, leading to structural damage and cracks.

How to Check for Engine Block Cracks

Checking for engine block cracks is an essential part of engine maintenance to prevent potential failures and costly repairs. To perform this inspection, ensure the engine is cool to avoid burns. Thoroughly clean the engine block’s surface to remove any dirt or oil that could obscure potential cracks. Next, use a flashlight to carefully examine the exterior of the engine block, paying close attention to areas prone to stress, such as around the cylinder head, coolant passages, and oil galleries. Look for visible cracks or signs of coolant or oil leaks, which may indicate a crack in the block.

Additionally, perform a pressure test on the cooling system to check for any abrupt pressure drops, which might indicate a crack that allows coolant to escape. Suppose you suspect a crack or notice any irregularities. In that case, it is vital to have a professional mechanic perform further diagnostics and repair work to ensure the engine’s integrity and avoid potential damage or breakdowns.

How to Fix Engine Block Cracks

Depending on the damage’s extent, several methods are available for repairing or replacing a cracked engine block. A specialist technician can weld the crack shut using special techniques and tools if the crack is minor. However, this is only sometimes possible as engine blocks are complex pieces with intricate geometries that make welding difficult. In such cases, a replacement engine block will be necessary if the damage exceeds what is acceptable for welding. It’s important to remember that even if a crack can be repaired by welding, the underlying cause of the damage must also be addressed; otherwise, it could recur in the future and potentially lead to further issues. Also read about Best Radiators for Ford.

Conclusion

Engine block cracks are a significant vehicle issue and can cause severe damage if not addressed promptly. It’s important to know the causes of engine block cracks and regularly check for any possible signs or symptoms as part of your engine maintenance routine. If you do find a crack in your engine block, it is essential to have a professional mechanic inspect it immediately and determine the most suitable fix. With proper care, you can ensure that your vehicle runs smoothly and reliably for years.

Freezing: If the engine is exposed to extremely cold temperatures without adequate antifreeze protection, the coolant can freeze and expand, exerting pressure on the engine block and potentially causing cracks.

Freezing: If the engine is exposed to extremely cold temperatures without adequate antifreeze protection, the coolant can freeze and expand, exerting pressure on the engine block and potentially causing cracks.

Add Comment